Material: SS304, 316, 316L, titanium, brass

Filtration accuracy: 1 - 300 micron

Size: Customized

Working temperature: -200 - 600℃

Sintered filter is widely used in industry. There are two different manufacturing processes, sintered metal filter, and metal powder filter.

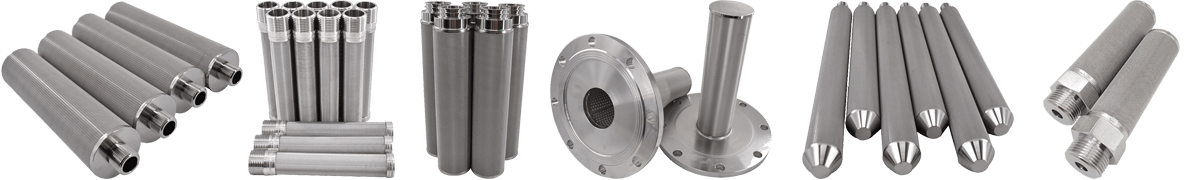

SINTERED METAL FILTER ELEMENT

Parameter

Material: SS304, 316, 316L

Filtration accuracy: 1 - 300 micron

Size: Customized

Working temperature: -200 - 600℃

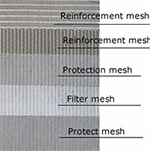

Material (sintered wire mesh)

Multi layer metal woven wire mesh, processed by vacuum sintering equipment according to requirements, it has very high mechanical strength.

Structure

The most common is five layers of wire mesh, However, sometimes, 7 layers of stainless steel wire mesh should be sintered together for environmental requirements.

Four part: Protection layer, filter layer, separation layer and supporting layer.

The mesh of multiple layers of wire mesh is interlaced to form a uniform and perfect filtration structure. It not only overcomes the inferior strength of ordinary wire mesh, but also increases the diversity of design. Including pore size, permeability, strength and so on.

Features

1. Surface filtration

2. Corrosion resistance

3. High temperature resistance

4. Stable filtration accuracy

5. High strength and steel property

6. Mesh hole smooth

7. Easy to clean and can be used repeatedly.

8. Easy to form, process and weld

It is an ideal filter material for high compression strength and uniform filtration size.It is suitable for continuous and automatic operation process. In this respect, other materials can not be satisfied.

Application

1. Water treatment

2. Precision filtration in machinery industry

3. Petroleum, chemical industry (High temperature and corrosive liquids)

4. chemical fiber

5. Dispersed cooling material

SIINTERED POWDER FILTER

Sintered metal powder filter uses metal powder as raw material, no need to add adhesive. Made by high temperature vacuum sintering. It can also be customized according to different needs.

Parameter

Product: Sintered powder filter

Material: SS304, 316, 316L, titanium, brass

Filtration accuracy: 0.5 - 200 micron

Size: Customized

Working temperature: -200 - 600℃

Sintered bronze filter element (sintered brass filter)

Filtration accuracy: 0.22 - 50 micron

Diameter: 30 – 80 mm

Length: 100 – 1000 mm

(All specifications can be customized)

Application: Gas and liquid filtration and gas distribution

It has high efficiency of filtration and noise elimination, high temperature resistance, corrosion resistance and high tensile strength. Suitable for working conditions in different environments, used as gas and liquid filter elements.

Good osmotic filtration performance and high filtration accuracy, as well as certain strength and toughness, it can be used at 300 degrees.

Application

1. Water treatment

2. Pharmacy

It is widely used in the pharmaceutical industry, especially titanium materials.

In the pharmaceutical industry, decarburization and filtration in large infusion, small injection, eye drops and oral liquid concentration and security filtration in dilution links.

Removal of impurities in API production process, decarbonization and filtration of materials

3. petrochemical industry

4. Food and beverage

5. Catalyst filtration

6. Probe protection for sensors

7. Fly ash treatment

Sintered filter VS Sintered powder filter

They are all processed by vacuum sintering equipment.

There are many similarities, each has its own advantages. As a professional manufacturer of metal filter elements, without special requirements, I also recommend using stainless steel sintered mesh filter.

1. Material (stainless steel wire mesh VS Metal powder)

Obviously, metal powder has a very big defect, easy to fall off after long use. It is easy to pollute the filtrate.

Stainless steel wire mesh does not cause this problem.

2. Service life

Their raw materials are the same, but because of their differences in structure and production technology, their service life is different. Surface filtration VS deep filtration.

The result is obvious, the former is easier to be clear, and can be used repeatedly.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved