Product: air filter

Material: SS304/316/316L

Size: 85*38mm or customizable

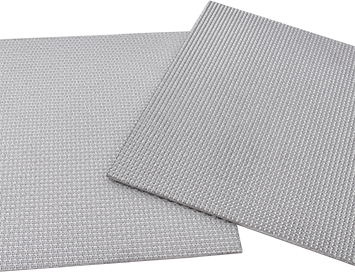

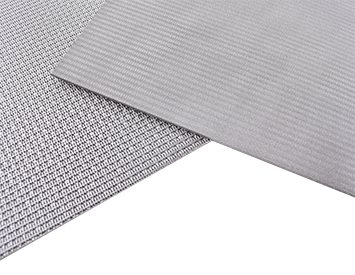

Type: mainly sintered wire mesh filter element (3,4 or 5 layers)

Application: mainly in purification system of infrared carbon and sulfuir analyzer

Infrared carbon and sulfur analyzers require high-purity analytical gas and motive gas to complete detection. The analytical gas is generally oxygen with a content of 99.5%. The motive gas uses purified nitrogen or compressed air. In order to ensure the accuracy of the analysis results, the infrared carbon and sulfur analyzer has a built-in purification system to remove the analytical gas, motive gas and other gases or Impurities and dust in the liquid, etc.

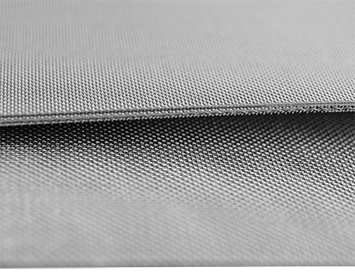

Sintered mesh filter elements are generally used in purification systems, and the most suitable size (85*38mm) and pore size (generally 1, 2, 5 or 10 microns) are customized for the infrared carbon and sulfur analyzer. Sintered mesh is a porous sintered material made of stainless steel wire meshes stacked together according to different structures, and then sintering, pressing, rolling and other processes. Generally, it has 5 layers: protective layer, filter layer, separation layer, strengthening layer and support layer. This filter element have stable filtering precision and high strength and stiffness.

1. The filtration precision is high, and the mesh size of up to 1 micron ensures the interception efficiency of impurities.

2. Good strength: due to the support of the forth and fifth layers, it has high mechanical strength and compressive strength, effectively resists the pressure of gas input

3. High temperature resistance: can withstand high temperature of 600℃

4. Corrosion resistance: due to the use of SUS316L, SUS304 stainless steel, it has strong corrosion resistance.

5. Long service life.

1. The material we used is a top grade stainless steel wire mesh, and sintered 5 layers together.

2. Our filter wire mesh uses both the diaanalyzer and weft mesh sizes, which are normal.

3. The filter mesh has no mesh defects, and the material complies with the national standard.

The nickel and chromium content are both standard.

4. We comply with national standards for materials, and all products are packaged independently before leaving the factory.

We have certificates of conformity, material certificates, inspection reports, and laser marking.

5. Custom according to your requirements.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved