Liquid cooling systems for servers and data centers are high-efficiency cooling technologies developed in recent years to address the heat dissipation demands of high-density computing. These systems use liquids (such as water, mineral oil, or fluorinated fluids) to directly or indirectly cool heat sources, offering significantly higher efficiency compared to traditional air cooling. Below is an overview of the system and the key applications of angle and Y-strainers.

I. Classification of Server/Data Center Liquid Cooling Systems

1. Direct Liquid Cooling (DLC)

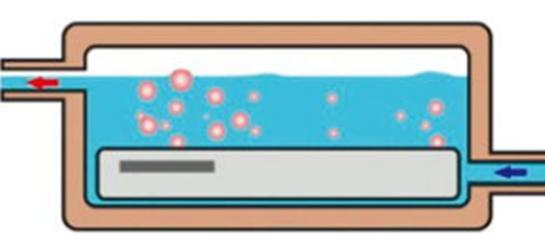

- Immersion Cooling: Servers are fully submerged in dielectric coolant (e.g., 3M fluorinated fluids), with heat dissipated through phase change or single-phase circulation.

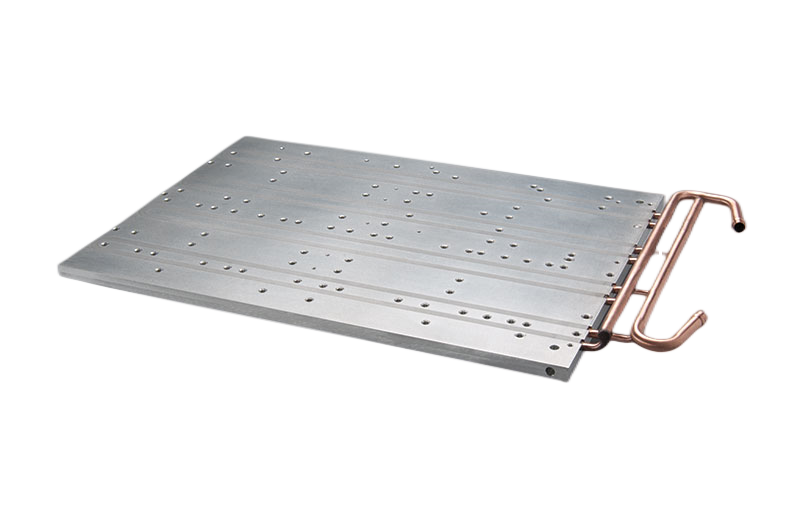

- Cold Plate Cooling: Liquid flows through metal cold plates in direct contact with CPUs/GPUs to absorb heat (e.g., Intel’s Submersion Cooling).

2. Indirect Liquid Cooling

- Coolant transfers heat via a secondary loop, with final heat rejection handled by external cooling towers or dry coolers.

II. Key Components and Workflow of Liquid Cooling Systems

1. Circulation Pump: Drives coolant flow.

2. Heat Exchanger: Transfers heat to the external environment.

3. Filters: Protect the system from particulate contamination and ensure smooth fluid flow.

4. Control System: Monitors parameters such as flow rate, temperature, and pressure.

III. Application of Angle Strainers and Y-Strainers

1. Angle Strainer

- Structural Features: Inlet and outlet ports form a 90° angle, with an internal cylindrical or basket-type filter screen, making it suitable for tight spaces where piping changes direction.

- Applications:

- Immersion Cooling: Installed before pumps or heat exchanger inlets to filter particles from degraded seals or gaskets.

- Cold Plate Branch Piping: Positioned at turns to capture metal debris or welding residues, preventing clogging in microchannels.

- Advantages: Space-saving, can replace pipe elbows, and reduces pressure drop.

2. Y-Strainer

- Structural Features: Y-shaped body with an inclined filter screen, connected via flanges or threads for easy cleaning without pipe disassembly.

- Applications:

- Main Circulation Line: Protects precision equipment (e.g., pumps, flow meters) from particle damage.

- Coolant Fill Port: Filters impurities during coolant replenishment to prevent system contamination.

- Advantages: Large flow capacity, low pressure drop, and easy maintenance.

IV. Key Parameters for Filter Selection

1. Filtration Rating: Typically 80-200 mesh (~74-180μm), balancing filtration efficiency and pressure loss.

2. Material Compatibility: Stainless steel (316L) for corrosion resistance, suitable for deionized water or fluorinated fluids.

3. Pressure Rating: Must match system operating pressure (commonly ≥1.6MPa).

4. Maintenance Design: Models with drain valves minimize downtime.

V. Real-World Examples

- Google Data Centers: Use Y-strainers in cold plate systems to protect circulation pumps, with 100-mesh filtration and EPDM seals + stainless steel screens.

- Bitcoin Mining Immersion Cooling: Angle strainers are deployed at tank outlets to prevent carbon deposits in mineral oil from entering heat exchangers.

VI. Future Trends

As liquid cooling adoption grows, filters will evolve toward smart designs (e.g., integrated differential pressure sensors) for real-time clogging monitoring and integration with Data Center Infrastructure Management (DCIM) systems for predictive maintenance.

By properly configuring angle and Y-strainers, the reliability and lifespan of liquid cooling systems can be significantly improved, while reducing failure risks caused by particulate contamination.

View the video:

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved