Benefits of Using Stainless Steel Filter Baskets Instead of PP Filter Bags

✈ 1. Durability & Longevity

- Mechanical Resistance: Stainless steel baskets resist impact, deformation, and cracking, making them suitable for high-pressure or high-flow conditions. PP bags are prone to punctures and degrade over time.

- Longer Lifespan: Stainless steel is reusable, reducing replacement frequency, while PP bags are disposable or require regular replacement.

✈ 2. Temperature Resistance

- High-Temperature Suitability: Stainless steel (e.g., Grade 304 withstands 500°C+) is ideal for hot liquids or steam cleaning. PP typically tolerates only 80–100°C and may deform.

✈ 3. Chemical Stability

- Corrosion Resistance: Stainless steel (e.g., Grade 316) resists acids, alkalis, and organic solvents. PP is stable with mild chemicals but may degrade in strong oxidizers or halogenated solvents.

✈ 4. Eco-Friendliness & Cost Efficiency

- Less Waste: Reusable stainless steel reduces plastic waste from disposable PP bags.

- Lower Long-Term Cost**: Higher initial investment but eliminates recurring expenses on replacements.

✈ 5. Cleaning & Maintenance

- Easy Cleaning: Stainless steel can be cleaned via high-pressure water, ultrasonic washing, or sterilization, ideal for food/pharmaceutical industries. PP bags may retain residues or require complex cleaning.

- Anti-Clogging Design: Some stainless steel baskets feature self-cleaning mechanisms (e.g., backflushing), whereas clogged PP bags must be replaced.

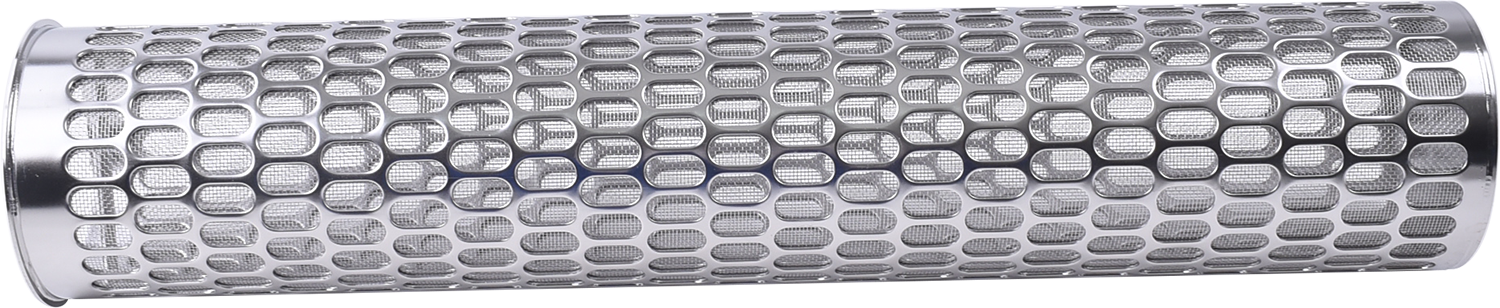

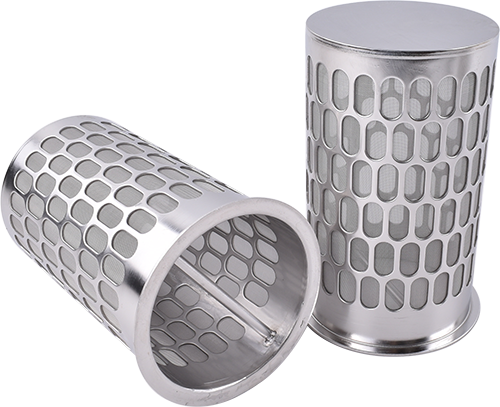

✈ 6. Filtration Precision & Flow Rate

- Customizable Pore Size: Stainless steel mesh can be precision-welded for consistent filtration under high flow. PP bags may deform under pressure, affecting accuracy.

✈ 7. Hygiene Compliance

- No Leaching: Stainless steel meets FDA/EU food-contact standards without releasing additives. PP may leach trace organics under heat or prolonged use.

✈ 8. Versatility

- Wider Applications: Suitable for extreme conditions (high temp/pressure/corrosion), while PP bags have material limitations.

Potential Drawbacks

- Higher Upfront Cost: Stainless steel baskets are more expensive initially.

- Heavier Weight: May increase equipment load.

- Rust Risk: Lower-grade stainless (e.g., 201) may corrode in chloride-rich environments.

Recommended Applications

- Food/Pharma: Processes requiring sterilization or CIP (clean-in-place).

- Chemicals/Electroplating: Filtration of strong acids, alkalis, or solvents.

- High-Flow Systems: Water treatment, oil filtration, or other high-throughput needs.

Stainless steel filter baskets excel in durability and sustainability, but the choice depends on specific needs (cost, media, hygiene requirements).

Huanzheng is an ISO9001:2015 certificated manufacturer of stainless steel filter housing and elements, provide custom service, contact us or leave message, let's know what are you interested in.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved