DSM Screen For Separation & Screening - Sieve Bend Screen

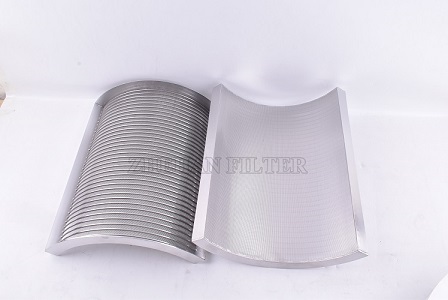

DSM screen is also called sieve bend screen, static V wire screen curved screen. ZHEHAN® provides customized processing services for DSM dewatering screens.

What is a DSM screen?

DSM screen is also called sieve bend screen, static screen, run down screen and curved screen. It is made of wedge wire screen panels as the raw material, bent at the required angle.

The DSM screen is made by bending the wedge wire screen panels, the wedge profile wire and the support rod are firmly welded together by the ring fusion welding technology.

Continuous V-shaped wire slot structure makes it have a larger opening area and is not easy to block.

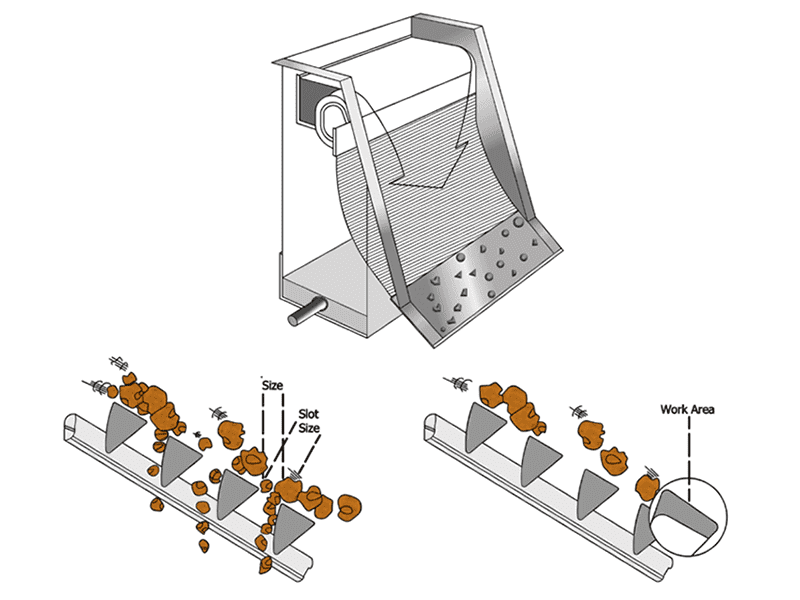

The curved surface has a higher screening capacity than a flat screen surface. Therefore, DSM screens with various bending angles are widely used in industrial dewatering, screening and solid-liquid separation.

--------------------------

Specifications of DSM screen (Sieve Bend Screen)

l Material: SUS304, 316, 316L. Carbon steel.

l Slot size: 50, 75, 100, 150, 200, 250 microns.

l Profile wire (conventional): 1 x 2, 1.5 x 2.5 mm.

l Support wire (conventional): 2 x 3, 3 x 5, 4 x 6 mm.

l Arc length: 400, 800, 1200, 1600, 1800 mm or as your need.

l Angle: 30° 45° 60° 90° 120° 270° 300°or as your need.

Technology

l Designing an appropriate angle of tilt of the wedge wire can improve the screening capacity.

l Increasing the percentage of opening rate can improve the screening capacity of the DSM screen.

ZHEHAN® can produce wedge wire with a width of 0.5 mm, and the opening rate can be increased by 50%.

l ZHEHAN® has developed a special surface treatment process to improve the abrasion resistance of the DSM screen, increase the service life by 30%, and reduce operating costs.

Characteristics of DSM Screen (Sieve Bend Screen)

l High screening efficiency, not easy to block.

l Rugged, compact and efficient.

l Static screen, no moving parts, gravity feeding, low energy consumption and low cost.

l No maintenance.

l The splicable independent parts are suitable for various construction environments.

--------------------------

Application of DSM Screen

Dewatering - Screening - Media recovery - Solid liquid separation - Equipment parts

l Industrial water treatment, dewatering, sizing and wastewater cleaning

l Cooling water and condensate filtration

l Mineral processing and screening, coal mine scrubbing and washing

l Chemical industry

l Food processing and corn wet milling equipment (120 Degree)

l Sugar factories

l Starch and pulp processing

l Modern fish and shrimp farming.

l Textile mill

For dewatering equipment

Dimension: 1800 x 6000 mm

Slot size: 700 microns.

ZHEHAN® has 45° and 120° conventional sieve bend screen stocks, which can be shipped within 3 days.

l 45° : thickening and screening.

l 120°: Pulp thickening, recovery, separating water suspension and separation of fibers.

Contact us or leave message if you are interested in this product.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved