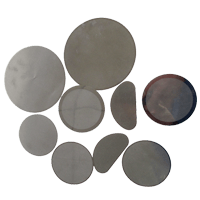

The extruder screen is an important part of the extruder and can be filtered to produce a qualified product. The extruder screen is used for filtration and blending of various viscous materials and products in the production of plastics, chemical fiber, rubber, hot melt adhesives, adhesives, coating materials, and mixtures. The extruder filter has a mesh type and mesh belt type. The extruder can automatically replace the filter through the automatic screen changer. It saves time and labor, and product performance is stable. Filtration time reduces production costs.

Specification of the extruder screen

Material: SS304, 316, 316l

Mesh: 20~150 mesh

The mesh of most filters is a square weave, the number of wires in each direction is the same. The Dutch weaving method uses thick wire in the horizontal direction and is specified as a double number. For example, 32 x 120 roots/in (1 in = 25.4 mm). Filters made by the Dutch weaving method do not require a parallel screen in the filter unit to provide fine filtration.

The pore size of the filter mesh having the same number of mesh eyes is determined according to the diameter of the wire, and it is not necessary to be completely identical. For example, a 20-mesh filter made of wire with a line spacing of 24 inches and a diameter of 0.02 inches has an opening of 0.01 in each side; and a wire made of 30 in. and 0.01 in diameter. A 20 mesh screen with a slightly larger opening on each side of 0.04 in. This is because the fine wire is not sufficiently fine to filter and is more likely to clog (1 in = 25.4 mm).

In general, the filter unit is installed in such a way that the coarsest screen faces the protective sheet and the thinnest screen faces the extruder. For example, the filter arrangement from the protective plate to the extruder may be 20 mesh / 40 mesh / 60 mesh, because this arrangement can prevent the filter from being blocked and can "blown" the impurities into the protective plate. Inside the opening.

If the finest screen is 80 or more mesh, a rough filter can be placed in front to prevent the filter from being rotated by the molten material or blocked by large impurities (eg 20/100/60/ 20 mesh arrangement). Since this type of device is identical from both sides, in order to ensure that they are not reversed, a symmetrical arrangement (20 mesh / 60 mesh / 100 mesh / 60 mesh / 20 mesh) is sometimes used.

Some processors deliberately reverse the filter and allow the coarse filter to filter larger particles on the upstream surface. They believe that this method allows more of the side molten material to pass through and decomposes less material on the upstream surface of the protective sheet.

Influences

The filter screen of the extruder is fixed to a porous or grooved protective plate to form a seal between the extruder and the mold. A clean filter produces less pressure and maybe only 50 to 100 lb/in2 (1 lb = 0.4536 Kg, 1 in = 25.4 mm). As the pressure increases, the number of impurities in the resin trapped on the filter web increases, thereby clogging the filter.

The filter will affect the temperature of the molten material

When the blocked filter is replaced, the pressure suddenly drops and the temperature of the molten material may also drop, causing a change in the size of the product. In order to maintain the same size of the product, the screw speed of the extruder can be adjusted, and the linear speed of the extruder can also be adjusted. These variations may not cause serious problems when extruding around the product, but changes in the temperature of the molten material may affect the form factor of the product when extruding a flat or irregularly shaped product. For example, in a flat mold, the cooler molten material may cause the center of the sheet to be thinner and the periphery to be thicker. This can be corrected by automatic or manual adjustment of the mold.

Behind the filter inverter, a gear pump that ensures that the molten material enters the mold stably can prevent the above problems. However, the temperature change that occurs after the molten material is replaced by the filter still needs to be solved by adjusting the mold. At the same time, since the gear pump is easily damaged by hard impurities, the gear pump also needs to be protected by a fine filter.

Some hard PVC processors are reluctant to use filters because the filter will increase the temperature of the PVC molten material and tend to degrade. This requires materials with better thermal stability, which increases the cost of the material. If you use a PVC-specific filter converter, it will also increase the cost. Therefore, most rigid PVC processors either shun the filter or use a coarse filter without a converter to filter only the larger particles.

Steel wire is the most commonly used metal filter material for extruders.

In general, the filter mesh (or the number of wires per inch) is 20 to 150 or more.You can place a rough filter on the front (such as the 20/100/60/20 mesh arrangement). Because the type of device is the same from both sides, in order to ensure that they will not be reversed, sometimes a symmetrical arrangement (20 mesh / 60 mesh / 100 mesh / 60 mesh / 20 mesh)

Filter considerations

Since the wire mesh is prone to rust, avoid moisture during storage, otherwise, rust will appear in the extrudate. More seriously, the rust filter is prone to breakage and the filtered impurities are leaked. Therefore, the filter should be stored in a plastic bag or rustproof paper.

When the PVC material is being squeezed, never place the bare filter on the extruder head. This is because hydrochloric acid in the air near the die of the head will corrode it. The best practice when extruding PVC is to install a fume hood above the die and be sure to keep the spare filter away from it, even after it has been bagged and placed in the freezer.

When the cleaning and cleaning of the protective plate are easy, the rewinding phenomenon is likely to occur, the sealing surface is damaged, and the sliding surfaces are not matched, thereby causing leakage. This will not only cause cleaning time, but also leaked molten material may affect the thermocouple value, damage the heater, and sometimes even cause the fire.

For a single-exhaust, two-stage extruder, if the back pressure at the filter becomes larger, the second stage of production will be reduced, but the production of the first stage will not be affected. When the back pressure is increased to approximately 2500 lb/in2 (1 lb = 0.4536 Kg, 1 in = 25.4 mm), the molten material from the first stage begins to leak into the vent. To avoid this, be sure to replace the filter when the pressure is low. In addition, the gear pump behind the filter device also prevents the molten material from leaking into the vent hole.

If the filter is filtered into large pieces of debris (such as paper), it will suddenly fail completely, which will quickly bring the pressure of the extruder to a peak. Therefore, in order to prevent this from happening, there must be a safety system such as a safety diaphragm, a safety pin or an alarm connected to the pressure gauge.

Purchase considerations of the extruder screen

There are many manufacturers of extruder filters in China. What do we need to pay attention to before purchasing?

- Verify manufacturer information

When we need a low price, we don't want to meet a trader, so we must first determine if your partner is a real manufacturer. There are many ways of verification, such as providing plants, equipment, workshop photos, etc.

- Quality inspection

You can make a sample list and check the quality of their products, including filtering accuracy, size and so on.

- After sales service system

This is rarely noticed by users.

When you bought bulk filters from China, after receiving the goods, you found a great deal of difference from the samples. This is a very troublesome matter. Believe me, it is as important as product quality, The contract should have the after-sales service terms promised by the supplier.

Zhehan is a professional manufacturer of extruder screen, If you need related products or other contents of the product, you can leave a message on the website.

Relevant articles

Application of Basket Strainers in Conductive Agent Production

View More >Applicaton of Self-cleaning filter

View More >Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved