Because stainless steel sintered mesh has the advantages of stable filtration accuracy, good pressure resistance, high temperature resistance, corrosion resistance and processing performance, it is widely used in food, pharmaceutical, chemical industry, aerospace, machinery and other fields. Therefore, the purchase of a high-quality sintered mesh screen is directly related to the benefits of production. Therefore, when shopping, you should consider the following aspects:

1. Selection of materials

There are many kinds of stainless steel sintered mesh materials, each of which has its own characteristics and scope of use, so it should be selected according to its actual situation.

304 is suitable for less corrosive gas and liquid filtration, with the advantage of low cost.

316 and 316L are more corrosive and acid-resistant due to the addition of Mo, which is suitable for a stricter working environment.

2. Is it convenient to clean?

Because regular cleaning of sintered mesh screen is very necessary in production and life, whether the sintered mesh screen has the advantages of easy cleaning is directly related to the progress and benefits of production. The cleaning methods of sintered mesh plate include backwash, backwater, filter, ultrasonic, dissolution, baking, etc. Among them, the two commonly used methods are backwashing and ultrasonic cleaning. Share from Hebei Huanzheng Filter Equipment Co., Ltd.

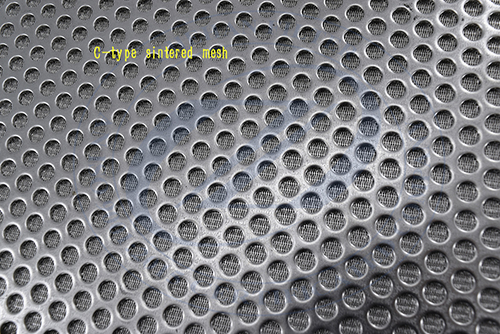

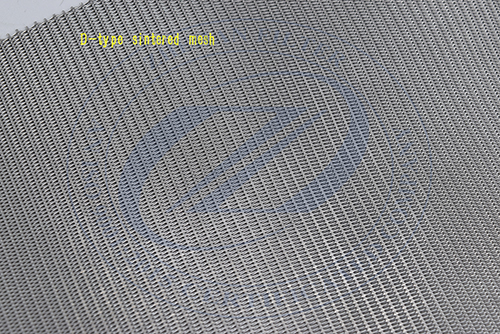

3. Selection of type of sintered mesh

The sintered mesh is divided according to different levels and screen structure. We are divided into four types: A,B,C,D.

Please refer to this site's introduction to sintered mesh types https://www.zhehanfilter.com/news/how-many-layers-of-stainless-steel-sintered-mesh.html

The advantage of Huanzheng® Sintered mesh

The production of Huanzheng sintered mesh has been strictly tested, and the quality of the product is guaranteed from the quality of the screen to the choice of packaging.

1. Wire mesh material inspection

inspect the material of wire mesh with spectrograph, and mark it to avoid mustakes.

2. Dead pixel inspection

Select high-quality wire mesh, use a flaw detector to check for dead pixel, no more than 10 dead pixel per square meter

3. The sintering furnace partitions are replaced in time, and new partitions are used for each batch

4. After high temperature sintering, the flaw detection is performed again, and the unqualified panel is removed.

5. Fumigation-free plywood box packaging, lined with bubble film.

We are profeesional manufacturer of stainless steel filter screen, filter elements, contact or leave message to us.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved