Whats the V wire screen?

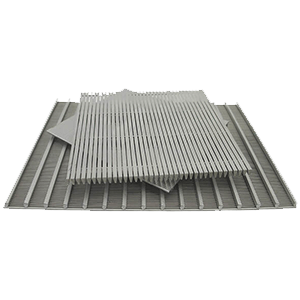

V wire screen is also called wedge wire screen because its body consists of V-shaped stainless steel wire, so many people call it V wire screen.

It is widely used in the oil, gas, water well and sand control industry in the worldwide. Its position in the well industry is especially prominent, and it is the most popular type of filter elements in the various liquid filtration process.

The full-welded v wire screen adopts a full-wound welding production process and is welded with a special trapezoidal wire winding on a set of support wires arranged in a circumferential arrangement. The whole welding ensures the strict continuous integrity of the product, which makes it form an ideal gap size and has the capability of bearing high pressure in maximum quantity.

The material of the v wire screen mainly includes the stainless steel 304, 316 and 316L, Monel copper-nickel alloy, low carbon steel and thermoplastic material, polyvinyl chloride and acrylonitrile-butadiene-styrene or alloy with PVC and acrylonitrile butadiene styrene as raw materials. Some other highly specialized materials can be used in special corrosive water filtration. While different filter screens can be made with different raw materials according to different customs needs.

Why do we say stainless steel v wire screen is the leader in the well sand control industry?

V wire screen tube is a special tube which installed at the bottom of a seamless or welded steel well tube, such as an oil well, a water well, a geothermal well, a brine well, etc, to separate the produced liquid from the sand in the formation. Because of the difference in the basic structure of the strata, sand particle size, produced fluid viscosity, the size and shape of the holes in the wedge screen tube are different. In recent years, with the rapid development of oil and mineral industry at home and abroad, the maturation of drilling and production technology in oil wells in desert areas, the increasing development of oil fields in the middle and late stages of oil fields, the rise of large-scale offshore oil production, geothermal wells and brine wells, With the rapid development of deepwater wells, the demand for stainless steel v wire screen consumption is increasing. The traditional drilling and production technology of drilling, casing running and blasting perforation is unable to meet the needs of modern drilling and production technology with complex terrain, high efficiency, and high recovery rate. So Sieve pipe has been widely used in underground liquid drilling. With the increasing demand of the market and the high difficulty in cutting the V wire screen slot, the high accuracy of hole seam' s size and shape. Both of them set up technical difficulties for the seemingly simple sieve pipe and sieve tube processing, raise the "economic" price, and thus cause great concern in many related industries.

The sieve tube is widely used in the regeneration of old wells in oil exploration, new well and exploration (test) wells, offshore oil mining wells and oil tubing, and effective sand control for the horizontal well, side drilling, and radial branch well. In our daily life, geothermal wells, brine wells, drought-resistant wells and domestic water wells are also used to control sand effectively. One word from an oil expert is the best way to explain the role of the screen, that is, "separate the honey from the honey and white sugar."

The application of the V wire screen

1.The oil fields oil well regeneration: a considerable number of oil wells in the world have now entered the middle and late stage of oil production, and the oil production has decreased year by year. In order to excavate the potential of the old oil well, the oil industry is solving the problem of reducing the amount of oil. they extend the area of underground oil collection by drilling "horizontal wells" sideways-----needed tube

2. New oil wells on land: because of the difference of geographical structure and oil layers, reducing the number of boreholes and ground pollution, the oil industries mostly drill horizontal wells at the bottom of the shaft which can reduce the number of vertical wells, save the cost and casing pipe and arable land.----need

3. Offshore oil drilling: the rise of large-scale offshore oil production in China and even the world, and the vigorous development of geothermal wells, brine wells, and deepwater wells----need

4. Sand control of oil extraction pipes: generally, oil pumping pipe also uses sieve tube to effectively prevent sand.-----need

How to select them?

1. V-shape stainless steel wire makes a Vee opening formed between the gap of the filter tube. The design is more efficient than other forms and ensures the smooth filtration of the liquid.

2. The continuous winding of SS wire forms a continuous high-density uniform slot on the supporting rods arranged in a circular pattern, which ensures the opening area and no obstruction of the filter tube and avoids the high-density accumulation of sediment.

3. The support rods spaced evenly around the circumference support the screen and prevent the screen from deformation.

4. The slot width on the surface is increasing towards the internal side of the screen. This slot geometry is called a keystone slot which has the ability of anti-plugging. Precise slot width should be designed to satisfy operational requirements. Usually, the slot width is two times the size of the formation sand.

5. The entire process of Fabrication is computerized to achieve the high order of precision and accuracy in the Final Product.

Related Reading

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved