The hottest topic in the past two years is undoubtedly AI, and AI requires a significant increase in servers and computing power, resulting in higher and higher power consumption of processors. To maximize the performance of processors, it is necessary to improve heat dissipation efficiency. . In this case, traditional air cooling technology is prone to problems, causing irreversible losses. Liquid cooling technology is a better solution. It is not only cost-effective, but can better control temperature and improve heat dissipation efficiency, and also saves costs for enterprises.

Liquid cooling system is a technology that solves the problem of high-density heat dissipation of servers. It was born in the 1980s, but it was mainly used by some ultra-large-scale Internet users and high-power computing users. It was not until the past two years that it was used in more and more data centers. Liquid cooling refers to a heat dissipation method that takes away heat from the server through liquid. Generally speaking, liquid cooling is divided into direct cooling and indirect cooling. At present, direct cooling is mainly based on immersion liquid cooling technology, which can be divided into phase change and non-phase change. Indirect cooling is mainly based on cold plate liquid cooling technology.

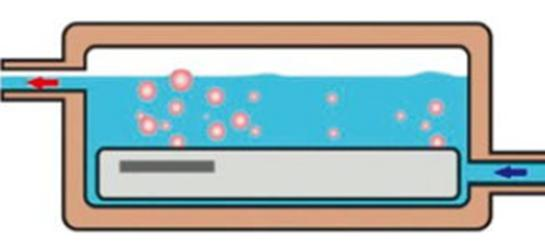

Immersion liquid cooling technology is a cooling technology that uses liquid as the heat transfer medium, the heating components are immersed in the liquid, and heat exchange is performed through direct contact. Popularly understood, liquid cooling uses liquid instead of air to take away the heat generated by IT heating components such as CPU and memory. It is like giving the server partial cooling, an overall "shower" or even a complete "bath". At present, common liquid cooling technologies include cold plate liquid cooling, immersion liquid cooling, and spray liquid cooling.

Liquid cooling technology can be divided into two categories: "indirect contact type" and "direct contact type" according to the contact method between the liquid and the heating device. Immersion and spray liquid cooling are contact liquid cooling, and cold plate liquid cooling is non-contact liquid cooling.

1. Immersion liquid cooling: Immersion liquid cooling immerses all the heating components of IT equipment in the coolant to dissipate heat. It is divided into single-phase liquid cooling and phase change liquid cooling according to whether the working fluid undergoes phase change. The coolant after absorbing heat is cooled or condensed by air cooling or water cooling.

2. Spray liquid cooling: Spray liquid cooling relies on pump pressure or gravity drive to accurately spray coolant from top to bottom to IT equipment circuit boards according to the needs of heating components. The heat-absorbing coolant is air-cooled or water-cooled. Circulating cooling method.

3. Cold plate liquid cooling: Cold plate liquid cooling is non-contact liquid cooling, and the cooling liquid does not come into direct contact with the heating device. Cold plate liquid cooling leads the coolant through flow channels to the cold plate that is in contact with the heating elements of the IT equipment to dissipate the heat. The coolant after absorbing the heat is circulated and cooled through air cooling or water cooling.

Compared with air cooling, liquid cooling has the advantages of low energy consumption, high heat dissipation, low noise, and low TCO. The cooling capacity of liquid is 1000 to 3000 times that of air. Liquid cooling technology can achieve the advantages of high density, low noise, low heat transfer temperature difference and universal natural cooling. It has incomparable technical advantages over air cooling technology. It is a kind of technology that can be applied to applications that need to greatly improve computing power, energy efficiency and Excellent cooling solution for deployment density and other scenarios.

1. Low power consumption: The heat transfer path is short, the low-temperature liquid is directly supplied to the communication equipment from the CDU (cold distribution unit), the heat exchange efficiency is high, and the heat exchange effect is better. At the same time, the refrigeration energy efficiency is high. Liquid cooling technology can realize high-temperature liquid supply of 40~55℃ without the need for a compressor chiller. It uses an outdoor cooling tower to achieve natural cooling throughout the year. In addition to reducing the energy consumption of the refrigeration system itself, liquid cooling is used for heat dissipation. The technology is conducive to further reducing the chip temperature. The lower chip temperature brings higher reliability and lower energy consumption. The energy consumption of the whole machine is expected to be reduced by about 5%.

2. Strong heat dissipation efficiency: Commonly used media in liquid cooling systems include deionized water, alcohol-based solutions, fluorocarbon working fluids, mineral oil or silicone oil, etc.; these liquids have excellent heat carrying capacity, thermal conductivity and enhanced convection heat transfer coefficient are much larger than air; therefore, for a single chip, liquid cooling has higher heat dissipation capacity than air cooling. At the same time, liquid cooling directly takes away most of the heat source heat of the equipment through the circulating medium; the demand for air supply for single boards, entire cabinets, and the entire computer room is greatly reduced, allowing the deployment of high-power density equipment; at the same time, more ICT can be arranged in a unit space equipment, improve data center space utilization and save land area.

3. Low noise: Liquid cooling technology uses a pump to drive the cooling medium to circulate and dissipate heat in the system, solving the heat dissipation problem of all heating devices or key high-power devices; it can reduce the speed of the cooling fan or adopt a fanless design, thus having excellent The noise reduction effect improves the comfort of the computer room operation and maintenance environment and solves the problem of noise pollution.

4.Low TCO: Liquid cooling technology has excellent energy-saving effects. Liquid-cooled data center PUE (power utilization efficiency) is the ratio of all energy consumed by the data center to the energy consumed by the IT load. The higher the PUE value, the higher the overall efficiency of the data center. Low.) can be reduced to less than 1.2, which can save a lot of electricity bills every year and greatly reduce the operating costs of the data center. Compared with traditional air cooling, although the application of liquid cooling technology will increase a certain initial investment, the investment can be recovered by reducing operating costs.

The advantage of the liquid cooling system is that it is quiet, has low noise, and uses anti-leakage technology, so there is no need to worry about liquid leakage.

1. Cloud computing: Cloud computing has long been the core of modern business, and liquid cooling technology can help data centers improve server performance and reduce maintenance costs, maximizing the provision of more efficient and reliable services for enterprise needs.

2. Super computing: Super computing requires a large number of processors and storage devices, and the workload is very high. Liquid cooling technology can provide better heat dissipation capabilities and initially improve the performance of supercomputers.

3. Large data centers (LSC): As the scale of data centers continues to expand, the operational deployment of thousands of servers has become more and more common. Liquid cooling technology can provide better heat dissipation capabilities and enable data centers to reduce energy consumption and costs.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved